In the core of Redox Flow Batteries, we find the electrochemical cell where the battery is charged/discharged. The Ion Exchange Membrane (IEM) electrically separates positive and negative side of the battery allowing the pass of ions through its structure closing the electrical circuit. This component plays a vital role on the battery performance affecting the coulombic and energy efficiencies, energy density, resistance, and the lifetime. Not only represent one of the most determining components of RFB but also represent a significant portion of the costs. Current IEM used in Vanadium RFB are the Nafion membranes®, this kind of membranes are based on perfluorinated polymers and represent approx.30 % of the battery costs. European Commission (EC) has planned to ban fluoropolymers because this kind of polymers are persistent, toxic, and can be bioaccumulated in organisms. So, research groups and companies have focused their attention on the development of membranes based on partially fluorinated or non-fluorinated polymers as well as new anionic, bipolar and amphoteric membranes which represent a more cost-effective solution. INO-HUB R&D team aware of the problems of fluorinated polymers and is investigating about different alternatives:

- The use of anion exchange membranes: It is true that Nafion membrane present high conductivity due to the high ionic mobility of protons. However, AEM membranes present better mechanical properties, lower crossover and represent an alternative more than 3 times cheaper.

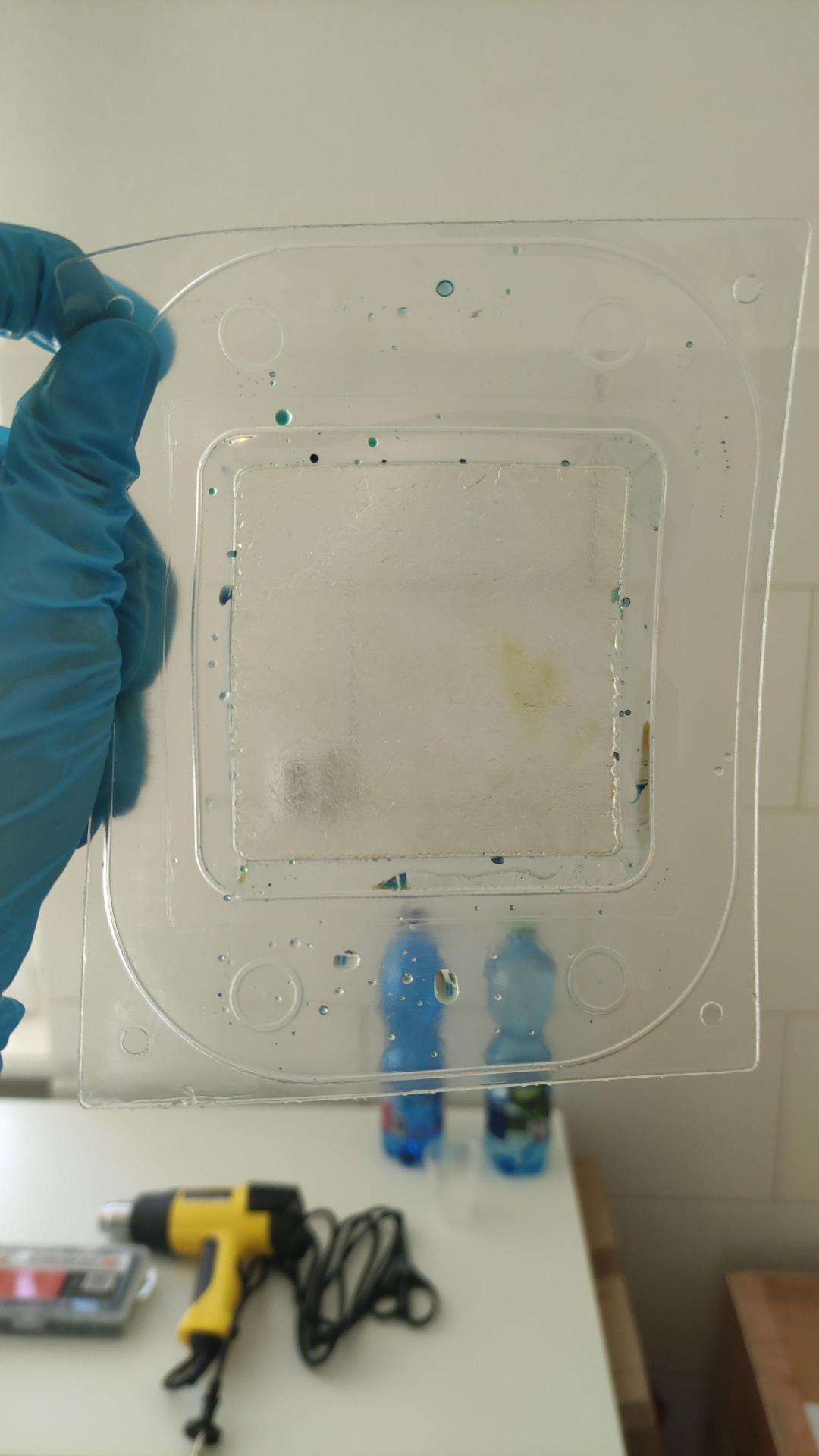

- Boost properties of non-fluorinated cation exchange membranes: As it has been discussed above Nafion membrane present many advantages due to the nature of the fluorinated polymers. An alternative is the use of non-fluorinated membranes which represent a more environmentally friendly candidate. So, the membrane properties could be boosted using different IEM modifications methods to decrease the crossover and increase membrane conductivity.

INO-HUB R&D team in collaboration with UPJS university is researching the effect of IEM modification in the battery performance trying to optimize the properties of non-fluorinated and partially fluorinated membranes. At the same time, the results of VRFB using CEM and AEM are going to be compared. AEMs present significantly lower crossover of vanadium species between tanks meaning that even if the performance is not so effective than Nafion membranes the needless of rebalancing as well as the lower price represent a very interesting appr

ACKNOWLEDGEMENT:

This work was supported by the project: IPCEI_IE_FLOW_BESS_012021