After the synthesis of 15 new promising organic electrolytes, the basic electrochemical characterization showed promising parameters such as high redox potentials (OCV of the battery should be higher than 1.0 V), diffusion coefficients (> 10-6 cm2/s), kinetic constants (> 10-3 cm/s), and water solubility (> 1.5 M). It is time to move one step forward, the single-cell experiments. The high reactivity of charged anolytes with oxygen requires to set up the battery in oxygen-free atmosphere. In this sense, a glovebox must be set up to avoid the discharging and disbalancing of the battery. The glovebox is connected to nitrogen/argon bottle to purge all the oxygen present inside the glovebox and an oxygen sensor is continuously measuring the oxygen concentration (< 1 %v/v must be kept inside) to avoid the misunderstanding between the performance of the redox active materials and the possible oxygen effect on them.

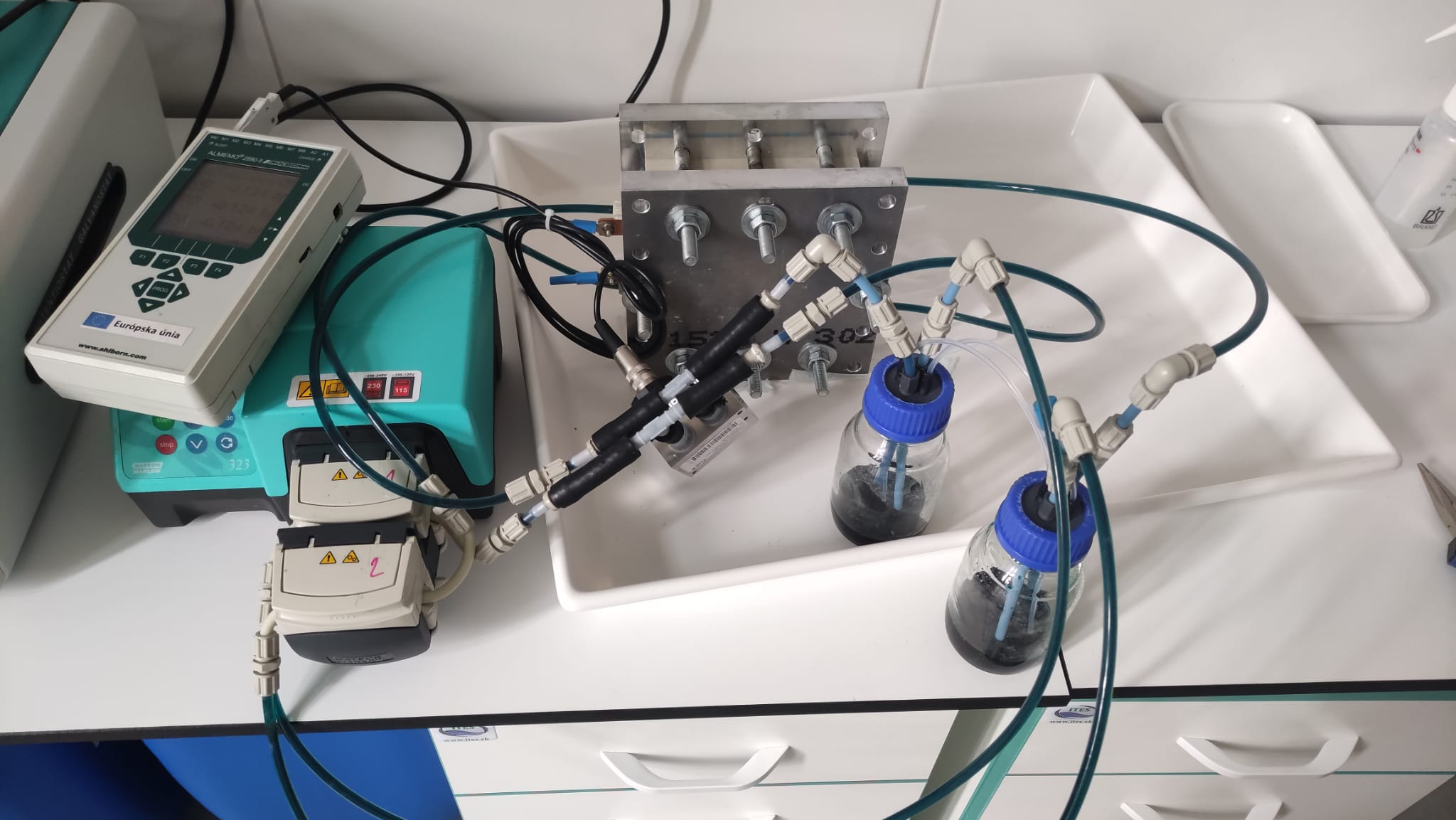

Furthermore, the new chemistries of the organic redox materials must be completely studied, in this sense, the water transport as well as the pressure drop of cell must be calculated for the new systems. In this sense a cell fully equipped with temperature, pressure, electrolyte level as well as OCV and OCP chambers has been set it up trying to gather the maximum information about our new systems. Showing after optimization of the systems <1 % water transport and reasonable pressure drops values (100 mbar) for a single-cell set up.

Gathering all these results, the optimum conditions for the new Aqueous Organic Redox Flow Batteries will be depicted and finally the vanadium electrolyte could be replaced in the stacks.

ACKNOWLEDGEMENT:

This work was supported by the project: IPCEI_IE_FLOW_BESS_012021