In the realm of energy storage, a pioneering technology is quietly reshaping the landscape. Vanadium-based redox flow batteries have emerged as a solution with the potential to transform how we store and utilize energy on a great scale. In this article, we’ll delve into one aspect of the production these innovative batteries, focusing on the critical role of sealing materials and our supplier preferences.

At the heart of this energy storage revolution lies a technology powered by vanadium. These redox flow batteries are designed not only to store large quantities of energy but also to do so with remarkable efficiency and recyclability. They hold the promise of securing our energy supply for years to come, making them an enticing prospect for both current and future energy needs.

The Crucial Role of Sealing Materials

In the manufacturing process of vanadium-based redox flow batteries, the choice of sealing materials is paramount. These materials play a pivotal role in ensuring the battery’s performance and longevity. For specialists in the energy industry, it’s imperative to understand the considerations that guide this selection process.

When researching suitable sealing materials, several key factors come into play:

- Compatibility: The chosen materials must be compatible with the battery’s electrolytes to maintain integrity and prevent leaks.

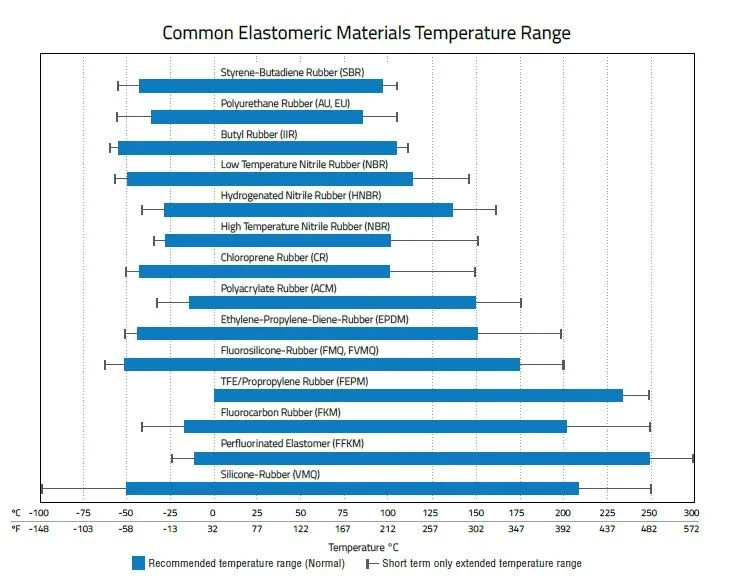

- Temperature Range: They should withstand a wide temperature range, from 0 to 50°C, to ensure reliable operation in various environments.

- Mechanical Flexibility: Mechanical flexibility is essential for molding processes like injection molding, a critical step in battery production.

- Availability: Easy access to these materials from reliable suppliers is crucial to maintain consistent production schedules.

Choosing the Right Materials

Regarding temperature resistance, most common sealing materials are suitable for vanadium-based redox flow batteries. However, when it comes to compatibility with the battery’s electrolyte, the options narrow down to three contenders: FFKM (Perfluoroelastomer), FKM (Fluorine Kautschuk Material), and EPDM (Ethylene Propylene Diene Monomer).

Source: https://www.gallagherseals.com/pub/media/magefan_blog/2015/11/templimits.jpg accessed on: 20.07.2023

FFKM and FKM, being fluorocarbon-based fluoroelastomers, offer superior chemical resistance. Still, their stiffness can be a limitation due to their long-chain flourine-based chemical structure. To strike a balance between chemical resistance and mechanical flexibility, we’ve chosen FKM and EPDM for our sealing process. This ensures both performance and cost-effectiveness, making it an ideal choice for the energy industry.

Supplier Preferences for Energy Specialists

In the world of sealing materials, the market offers a multitude of suppliers. Our preference is to source materials from European suppliers. This decision aligns with our commitment to quality and reliability, ensuring shorter and more predictable delivery times—a crucial factor in meeting the demands of an ever-evolving energy landscape.

In conclusion, vanadium-based redox flow batteries represent a remarkable leap forward in energy storage technology. For specialists in the energy indus

ACKNOWLEDGEMENT:

This work was supported by the project: IPCEI_IE_FLOW_BESS_012021