The production of every battery cell, regardless of its size, starts from the inception of models of all components. Then, utilizing modern software, we model the future cell behavior before the actual production of parts and ordering of the materials. The first battery parameter that could be evaluated from the model is the pressure drop of the cell, influenced primarily by the cell design and electrode materials.

To predict the pressure drop of INO-HUB small cells and battery stack, Dr. Natalia Podrojková, our colleague from the University of Pavol Jozef Šafárik in Kosice, undertook a comprehensive review of state-of-the-art literature on battery simulations and prepared several simulation models using Comsol software.

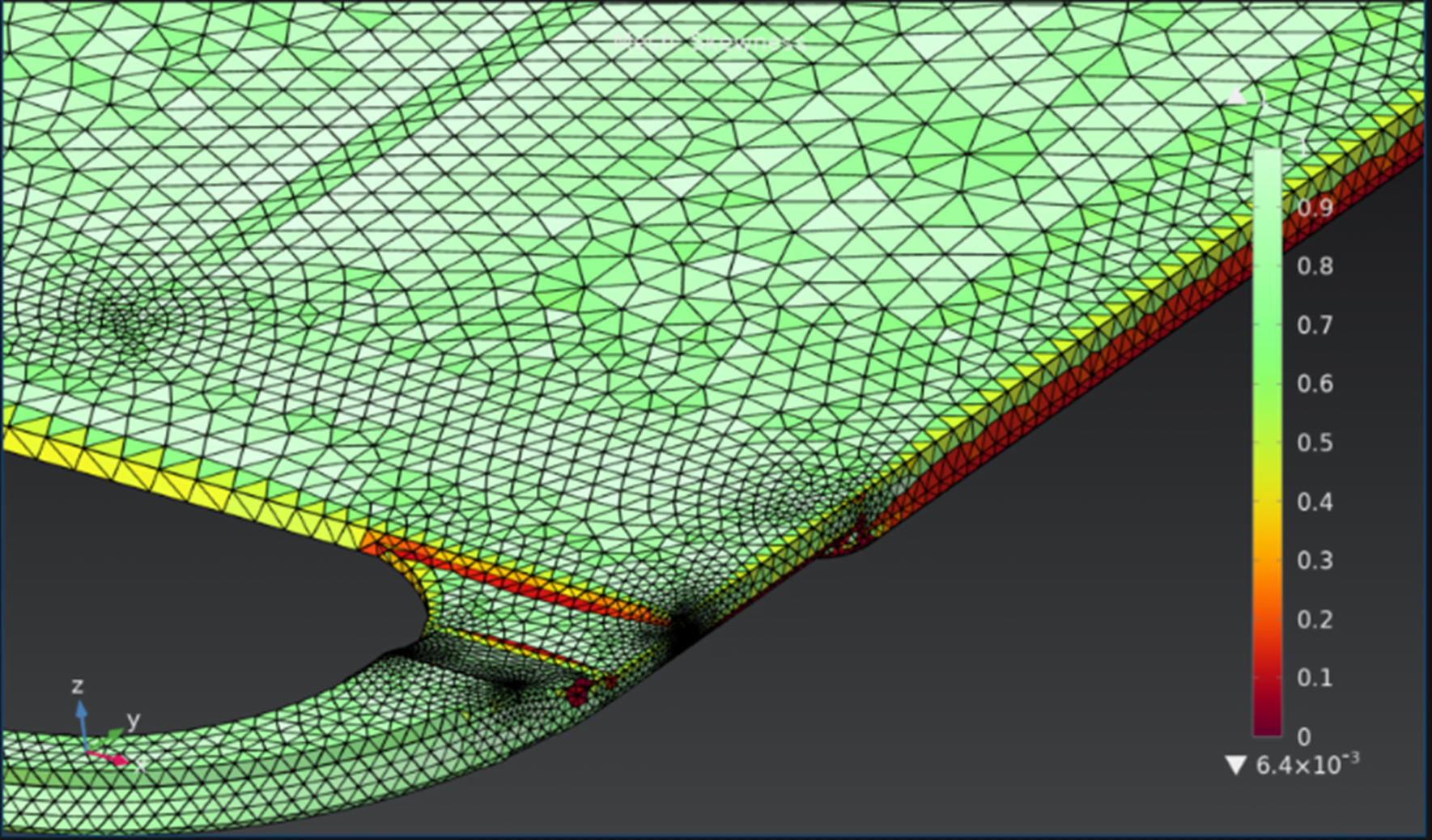

The preparation of simulation models involves the creation of a 2D cell geometry, followed by the transformation into a detailed 3D model. The simulation further encompassed the establishment of laminar flow physics and the creation of a geometry network for laminar flow physics.

Shortly, the simulated data will be compared with experimental values obtained for the small INO-HUB cells and battery stacks to refine and adjust the model, ensuring the accuracy of our battery design.

ACKNOWLEDGEMENT:

This work was supported by the project: IPCEI_IE_FLOW_BESS_012021